Analyzing the “plastics problem”

Figure 2. Plastic pollution, Ghana 2018 (left; Muntaka Chasant, CC BY-SA 4.0, via Wikimedia Commons) and possible trends of microplastics in the surface ocean (right; Our World In Data, CC BY 3.0, via Wikimedia Commons).

Figure 3. A “plastic-free” society. A biodegradable plastic free bag (left; Kgbo, CC BY-SA 4.0, via Wikimedia Commons) and some biodegradable cutlery (right; Andrea from Vancouver, Canada, CC BY-SA 2.0, via Wikimedia Commons.

Unquestionably, pictures like Figure 2 have a dramatic emotional impact on public opinion. As a scientist, though, I am used to analyze questions based on rationality, and let emotions come second. When I do that for the specific problem of interest here, I cannot but conclude that, on a planet which is home to 8 billion people who will soon grow to 10 billion or more, what is wrong in Figure 2 is not plastics in itself, but what society does with and around it. Telling the story right is part of my responsibilities of LSP Head; if you like, follow my reasoning until the end, and then make your own unbiased opinion.

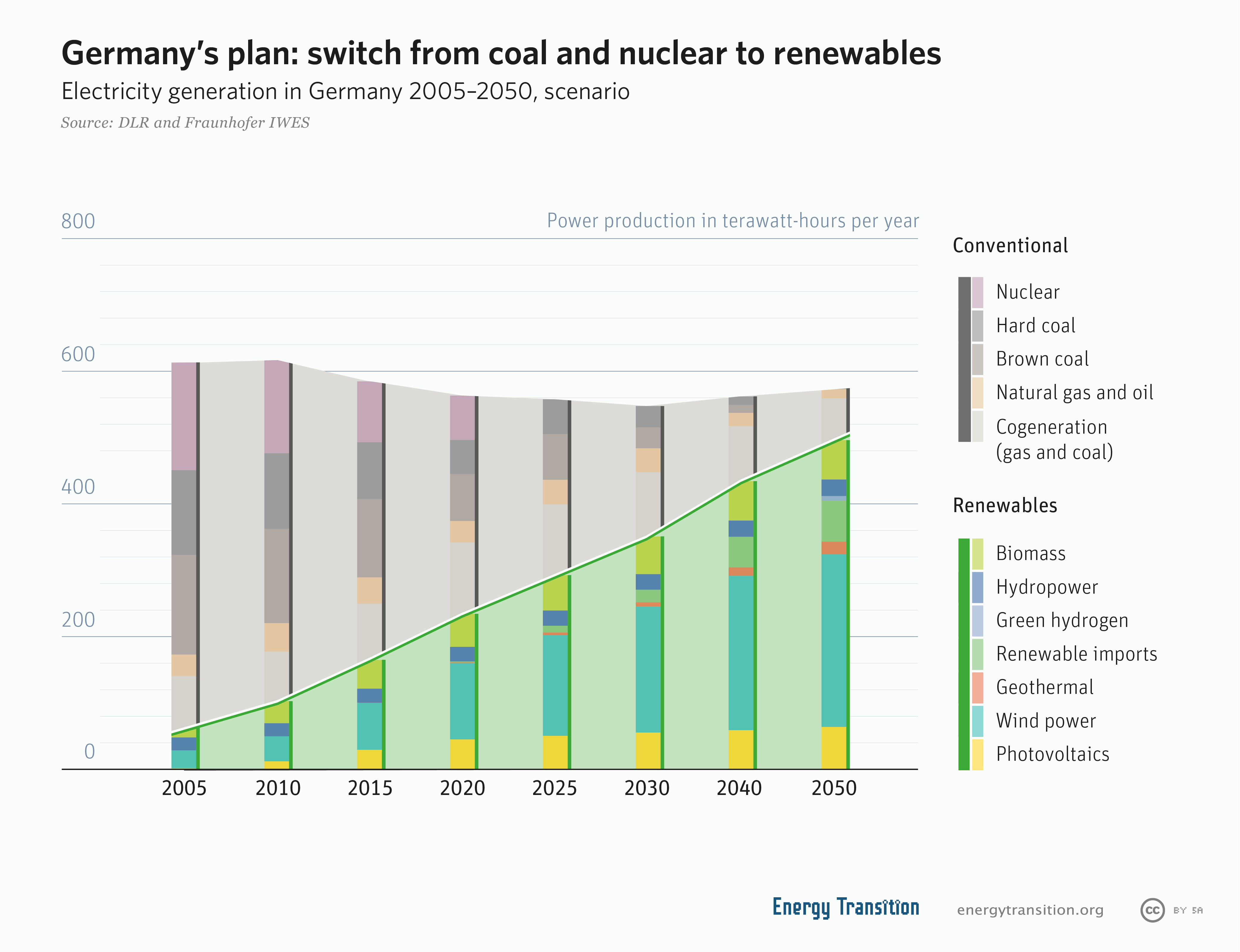

The story begins from the fact that human communities need energy: the way that need is satisfied depends on how large and advanced those communities are. Until few centuries ago most used to burn wood or charcoal, but already under the Romans that solution gave sign to be unsustainable. After switching to coal, air pollution grew to prohibitively high levels, and by the 1800s living in large urban areas had become very unhealthy. Oil, which was introduced in the early 1900s, burns cleaner than coal, and natural gas is even more so. In the new millennium, however, close to 10 trillion metric tons of fossil (hydro)carbons are combusted every year, corresponding to 40 trillion metric tons of CO2; suspecting that global warming is the consequence seems justified. The picture is about to change again: whereas nuclear fission, which for a while looked like an option, is being abandoned as too high-risk, and nuclear fusion still is far away, energy from renewable resources like sun and wind is ultimately at hands (Figure 4). At such a gigantic scale, transitioning from one energy production strategy to another can take a few decades (Figure 5), but if we are lucky CO2 levels will fade before a catastrophic and irreversible climate change occurs. Fossil (hydro)carbons can then be saved for industrial organic chemistry, which means a 100-fold reduction of scale compared to the present usage rate.

The plastic waste problem (Figure 2) is a perverse side effect of the current strategy of energy generation: large-volume polymers are mainly produced from the light fraction of refined oil, a ‘niche’ of several hundred thousand metric tons per year of molecules that would otherwise represent byproducts and are used instead as abundant and cheap monomers. Saturated hydrocarbon polymers are not biodegradable, and chemically inert other than for combustion (or pyrolysis under drastic conditions); this is one of their strong points, but also a major drawback because if, at the end of the life cycle, we make plastics become litter, it will stay in

the environment practically forever. The question is whether it makes sense to propose abandoning plastic materials because we are not good enough to prevent littering.

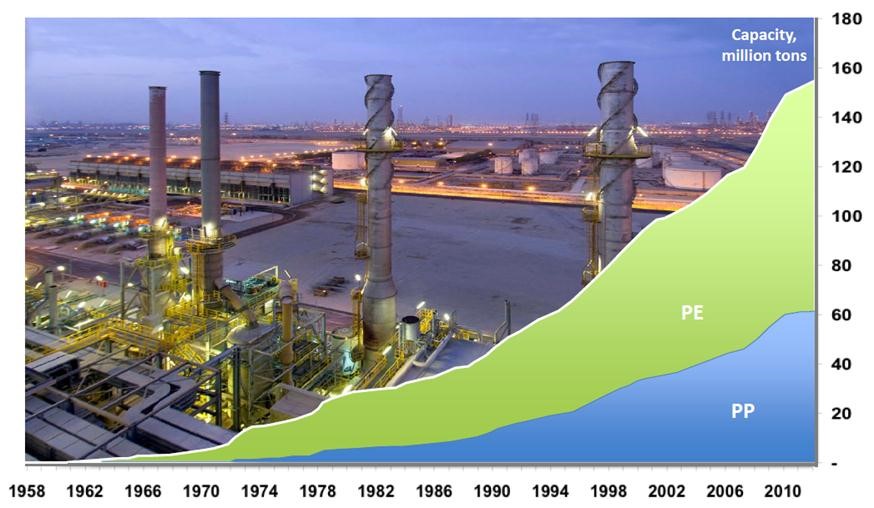

Wood, glass and metals, which are the possible alternatives, are all highly energy and resource intensive. As a matter of fact, when in the 1950s polyolefins (currently the major components of the plastics market) were invented, it was immediately clear that they would provide superior solutions to many acute societal demands (from smart packaging for food and all sorts of goods, to lightweight components and apparels for hundreds of different applications). Indeed, the global market of polyethylene and polypropylene based materials has been growing exponentially since then (Figure 6).

One does not need to be a genius to realize that, in a finite system, exponential growth is not sustainable, and that circular economy is the most sensible model for society. In the specific case under discussion, there is no question that continuing along the curve of Figure 6 is untenable; on the other hand, the idea of a “plastics-free” society (Figure 3) is at the same time naïve and unfeasible, both conceptually and practically. Discontinuing a production of 0.5 billion metric tons per year of indispensable materials when all conceivable alternatives feature a worse energy balance and carbon footprint (Table 1) would be suicidal. Yet, we must find ways to slow the exponential growth of Figure 6 and minimize the dispersion of plastics into the environment, so as to eradicate phenomena like that in Figure 2. Both targets are necessary and urgent and can only be achieved by means of an integrated strategy combining (a) fundamental and applied research leading to novel and smarter products and processes, and (b) different economic, organizational and civic educational models for society.

At LSP we are busy contributing to action (a), in collaboration with other scientists and many polyolefin producers and users; the next sections of this introduction will briefly explain how (other pages of this site will provide the details). Before concluding the present section, though, as an informed citizen I like to add a comment on action (b).

I firmly believe that all that we do should be inspired by common sense. Implementing a model of circular economy, which means reconsidering most paradigms of capitalism and consumer society, makes no exception. Recycling is one of the pillars of said model, which dictates that all materials at the end of their life cycle are recovered and re-used; common sense, in turn, suggests that any recycling protocols be economically viable. Paper, metals and glass are extensively recycled already. The case of plastics, instead, is more problematic, because producing recycled resins is currently far more labor and energy demanding than virgin ones, and the products moreover are inferior. In my opinion, we should agree that ideally all disposable plastic items are made with degradable polymers (possibly from renewable sources), whereas nondegradable plastic wastes which are too complicated and expensive to collect and/or recycle (e.g., ill-defined multi-material mixtures) are recognized for what they are, i.e. chemically pure hydrocarbons that can be safely disposed by means of incineration with energy recovery. With this I am not questioning that burning insane amounts of fossil (hydro)carbon for energy production means dilapidating our precious reserves of soft matter to make CO2 and must be stopped as soon and as much as possible. On the other hand, I am also convinced that combusting hydrocarbon wastes in high-tech incinerators, at a scale which is lower by two orders of magnitude than what we do now, is by far the most rational solution to the problem exemplified by Figure 2.

This being said, chemical recycling of plastics into monomers may be considered a special case, because the drastic reduction of oil cracking and refining processes to produce fuels can lead to a shortage of olefins for the polymer industry; many large petrochemical companies have already launched massive “oil to chemicals” R&D programs to overcome the problem, but additional independent streams of monomers from plastics recycling can be desirable, as long as that is not unreasonably expensive and the necessary chemical purity standards can be matched.

Introduction

LSP is a global competence center for fundamental and applied studies on olefin polymerization chemistry and catalysis.

Members

We hope you Enjoy discovering all the people that belong to the LSP Project. Visit us to discover more about our team.

Research

LSP specializes in fundamental and applied studies of catalytic olefin polymerizations, aiming to better understand and improve…

Infrastructure

LSP is one of the very few academic groups operating a comprehensive HTE workflow for organometallic catalysis.

Join LSP!

We are always interested in hearing from potential new members and collaborators who are interested in a position at LSP.

Visit

Whether you are a student, a scientist, a technologist, or an occasional traveler of the Web, visit us, get in touch.